A Record of Metal & Flame Welding Blog

More Guides

-

How to Choose a Cutting Wheel

Jan 23, 2026, 15:24 PM by User Not FoundChoosing the right cutting wheel is key to clean, efficient welding. Your choice depends on wheel type, grain, and thickness. Type 1 wheels offer sharp, precise cuts with a flat profile, while Type 27 wheels improve visibility and allow flush cutting. Ceramic alumina, zirconia, aluminum oxide, and silicon carbide each fit different metals and demands. Thickness affects accuracy and durability. Match the wheel to your grinder, material, and project to get smoother cuts and avoid rewelding.Full story -

How Can Robotic Welding Transform Fabrication Processes?

Oct 28, 2025, 09:26 AM by User Not FoundRobotic welding is reshaping modern fabrication by delivering faster production, lower costs, and higher-quality results. This blog explores how welding automation can streamline your workflow, reduce waste, and elevate product consistency. Whether you're considering a switch or scaling up, discover why robotic welding is a smart investment for competitive manufacturing.Full story -

How Welding Positioners Can Help Improve Productivity, Quality, and Workplace Safety

Aug 14, 2025, 10:53 AM by User Not FoundWelding positioners are crucial tools for modern fabrication, improving productivity, quality, and safety. By securely holding and rotating workpieces, they enable welders to create cleaner, more uniform welds, reducing inconsistencies and material waste. These tools also enhance worker safety by minimizing heavy lifting and improving ergonomics. Ultimately, positioners streamline workflows, reduce downtime, and are a key investment for any shop aiming to boost efficiency and consistency.Full story -

What Is Flux Core Welding Wire?

Aug 4, 2025, 11:32 AM by User Not FoundFlux-cored welding wires, filled with flux, offer versatility and high deposition rates, making them ideal for industries like shipbuilding, construction, and outdoor repairs. Available in gas-shielded and self-shielded types, they provide strong, reliable welds and are beginner-friendly. Benefits include portability, strength, and adaptability across materials, though slag removal is required. WeldingSupply.com offers an extensive selection and expert guidance to help you choose the right wire for your project and achieve optimal results.Full story -

How to Choose a Plasma Cutter

Jun 17, 2025, 16:56 PM by User Not FoundChoosing the right plasma cutter ensures precise, efficient metal fabrication. Key factors include material thickness, which affects amperage needs, input power (115V, 230V, or dual voltage for flexibility), and duty cycle, which determines how long the machine can run before cooling. Portability matters if you work in different locations, while operating costs like consumables impact overall expense. Plasma cutters offer speed, accuracy, and versatility. Find expert tools at WeldingSupply.com!Full story -

The History of Welding

Mar 18, 2025, 16:58 PM by User Not FoundWelding is key in today's world. It helps build everything from skyscrapers and ships to airplanes and new medical technology. Welding has greatly influenced humanity and its impact reaches far into the past and over centuries. It highlights our endless quest for innovation and progress. By looking at welding's origins, key milestones, and modern advancements, we see how this craft has influenced society for thousands of years.Full story -

The Benefits of Automated Welding: Revolutionizing Fabrication Processes

Mar 3, 2025, 14:08 PM by User Not FoundAutomated welding utilizes machines and computer programs to help make welding faster and more consistent. These systems follow set instructions to complete welding tasks with less help from people, which may reduce errors and improve efficiency. By keeping weld quality more uniform, automated welding can support better results across large projects. While outcomes can vary, many manufacturers use automation to meet production goals and stay competitive.Full story -

Welding Accessories for Beginner Welding

Feb 13, 2025, 09:54 AM by User Not FoundThis guide serves as a starting point for beginner welders, detailing the essential tools and accessories required to ensure safety, precision, and efficiency during the welding process. We'll walk you through the key facets of welding—from material preparation and workspace setup to selecting the proper equipment and consumables for different welding methods such as MIG, TIG, and stick welding. We'll also discuss the importance of post-weld cleanup to achieve durable, high-quality results.Full story

Welding Accessories for Beginner Welding

Starting your welding journey can feel daunting for some, but with the right tools and accessories, you can achieve professional results while keeping yourself safe and being efficient. From essential marking tools and welding magnets for material setup to protective gear like helmets, gloves, and respirators, beginner welders need a variety of accessories to build their skills and maintain a safe workspace. At WeldingSupply.com, you’ll likely find everything you need to prepare for success.

Welding is a vital trade that spans across industries such as oil and gas, construction, automotive, aerospace and many others. For new welders, having the right tools and accessories can make a significant difference as they learn to achieve high-quality results.

→ Welding Materials

→ Welding Preparation

→ Types of Welding

→ Post-Weld Cleanup

→ Frequently Asked Questions about Welding Accessories

Welding Materials

Proper preparation starts with laying out your materials accurately and securely. Marking your metal pieces and positioning them correctly can help ensure a precise weld. The following accessories are helpful when getting started:

New welders often rely on marking tools to designate welding lines clearly. Markers such as felt-tip paint markers and ball-point paint markers are popular options. For an affordable alternative, soapstone combined with soapstone holders is widely used in the welding industry. Soapstone creates visible, durable markings on metals, even withstanding some heat and weld prep activities.

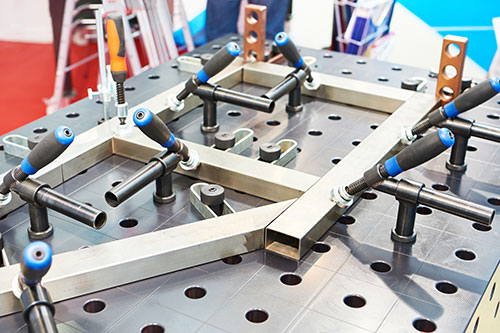

Welding magnets are indispensable when positioning and securing materials. Magnets are designed to hold metal pieces at specific angles, making it easy to create reliable 90-degree joints or other configurations. When used alongside other positioning tools, they allow for seamless alignment.

Welding clamps help to round out your toolkit for material layout. These clamps help keep metal components steady during the welding process, helping to make welds that are uniform and professional.

Welding Preparation

Preparation is key to safe and efficient welding. New welders should focus on setting up their work environment with proper safety gear, ventilation, and workspace tools.

Safety cannot be emphasized enough when welding. Proper PPE not only safeguards you from harm but also promotes better focus on your work:

Welding Helmets and Safety Glasses:

A protective welding hood is critical, but don’t overlook wearing safety glasses underneath. Even when your helmet is down, safety glasses protect your eyes from stray debris. WeldingSupply.com offers a variety of clear safety glasses in different styles and fit for all face shapes.

Protective Clothing:

Depending on the job, consider wearing a leather jacket, apron, or cape sleeve set for additional protection against sparks and arcs. Some styles even include pockets to keep frequently used tools within reach.

Respirators and Fume Extraction Systems:

Ventilation is an important part of protecting yourself against harmful welding fumes. Options like portable fume collectors, respirators, and shop fans can make a significant difference in maintaining a breathable workspace.

Anti-Spatter Spray

Spraying the weld area with anti-spatter spray before starting can significantly simplify post-weld cleanup. WeldingSupply.com carries specialized formulations designed to reduce the amount of spatter sticking to the welded surface.

Types of Welding

As a new welder, you will use one of three primary welding processes: Metal Inert Gas (MIG), Tungsten Inert Gas (TIG), or Shielded Metal Arc Welding (SMAW), also known as stick welding. Each process requires specific accessories and consumables to get the best results:

MIG welding is a versatile process used for a wide range of materials. WeldingSupply.com offers high-quality ER70S-6 welding wire, one of the most common welding wires for mild steel applications requiring tensile strength of up to 70,000 psi. We also stock varying grades of MIG wire for aluminum, stainless steel, and specialty metals.

TIG welding is ideal for precise welds on thinner materials. Accessories include TIG rods, tungsten electrodes, TIG welding packages and consumables. TIG welding can provide welders greater control over heat input, making it suitable for intricate applications.

Stick welding is a popular choice for outdoor and challenging environments due to its simplicity and versatility. We offer a variety of stick electrodes for different applications, ranging from mild steel to high-tensile alloys.

WeldingSupply.com also carries a full line of welding machines, including high-performance models from trusted manufacturers like Miller Electric, Lincoln Electric, ESAB, and HOBART to help new welders hone their skills.

|

|

|

| MIG welding | Stick welding | TIG welding |

Post-Weld Cleanup

Once the welding process is complete, proper post-weld cleaning and finishing can help you deliver the quality and durability your project needs. Depending on the welding method used, cleanup requirements may vary.

MIG welding cleanup:

When using solid wire with gas shielding during MIG welding, post-weld cleanup is minimal and typically involves removing soot or light spatter around the weld. Basic tools like wire brushes or grinders with wire wheels can easily handle this.

TIG welding cleanup:

TIG welding often requires little to no post-weld cleanup, though exceptions may apply. For instance, aluminum parts intended for anodization may need additional processing. Stainless steel welds may need pickling and passivation to restore corrosion resistance by removing and repairing the damaged surface oxide layer. WeldingSupply.com has specialized products for these tasks.

Stick welding cleanup:

Stick welding often leaves slag covering the weld, a hardened layer formed from the flux covering of the electrode. Removing slag may require chipping hammers, grinding tools, or wire brushes. Proper cleanup helps ensure the strength and good appearance of the final weld.

Additional Tools for Welders

WeldingSupply.com provides a broad selection of tools to support each stage of the welding process. From contact tips and clamps to welding robotics and automation systems, we’re here to equip welders with everything they need to succeed.

For new welders, having the right accessories and tools is essential to building solid skills and delivering high-quality results. WeldingSupply.com offers what you need, from pre-weld preparation tools to post-weld cleanup essentials. Visit our online store or stop by a WeldingSupply.com location to explore our extensive inventory.

Our knowledgeable staff can guide you in selecting products tailored to your specific processes and projects. Let WeldingSupply.com be your trusted supplier for welding supplies, providing you with reliable tools, excellent customer service, and technical support to kickstart your welding journey.

Visit WeldingSupply.com today for all your welding and cutting needs!

Shop Welding Accessories →

Frequently Asked Questions about Welding Accessories

What are the essential safety accessories for a beginner welder?

Beginner welders should prioritize personal protective equipment (PPE) to help them protect themselves when welding. Essential items include a welding helmet, safety glasses, welding gloves, and protective clothing like a leather jacket or apron.

What tools are needed for preparing materials before welding?

What tools are needed for preparing materials before welding?

Proper preparation is key to a good weld. Beginners should have a selection of tools for material setup. Suggestions include:

-

Marking Tools: Soapstone or felt-tip markers for drawing clear lines on metal.

-

Welding Magnets: To hold metal pieces at specific angles for accurate positioning.

- Welding Clamps: To secure materials and prevent movement during the welding process.

What are the main types of welding for beginners?

Three common welding processes for beginners are:

-

MIG (Metal Inert Gas) Welding: A versatile process that uses a continuously fed wire and is relatively easy to learn.

-

TIG (Tungsten Inert Gas) Welding: Known for producing precise, high-quality welds, particularly on thinner or specialized materials. TIG welding requires a high level of skill and control.

-

SMAW (Shielded Metal Arc Welding) or Stick Welding: A popular choice for outdoor work and challenging environments due to its simplicity and portability.

Why is post-weld cleanup important?

Post-weld cleanup is crucial for ensuring the durability or appearance of a finished project. The specific cleanup needed depends on the welding method:

-

MIG Welding: Often requires minimal cleanup, such as removing light spatter.

-

TIG Welding: Generally leaves a clean weld with little to no residue.

-

Stick Welding: Leaves a layer of slag that must be chipped away to reveal the finished weld.

What is the role of consumables in welding?

Consumables are parts and materials that are used up during the welding process and must be replaced. Examples include welding wire, electrodes, and tungsten, as well as tips, nozzles, collets, collet bodies and cups. Choosing the correct consumables for your specific welding process is essential for achieving the best results.